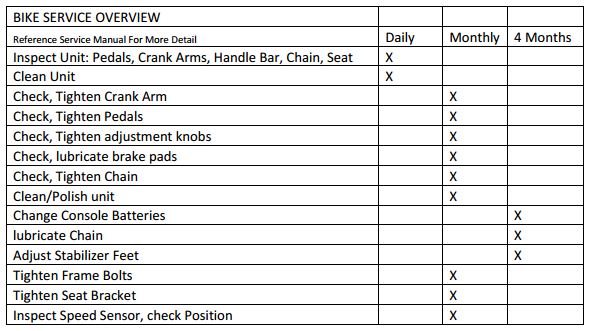

PREVENTIVE MAINTENANCE

Look, you can do very little to keep your bike in pretty good shape, that’s all in wiping it down properly after each use, but if you want to keep it in tip top shape, here are some tips to perform regular scheduled preventive maintenance procedures to maintain your sweet ride. Please note bike maintenance may differ from products.

TOOLS

Basic tool required for service and maintenance of your indoor cycling bike.

15mm Wrench

Metric Allen Wrench Set and Metric Sockets

Torx Wrench Set (only occasionally or not at all if you have a service professional out annually for residents and monthly for commercial)

Chain Lube

Cleaner/Furniture Polish

* Available at local bike or fitness-related stores.

DAILY MAINTENANCE

Dry the bike after each use to remove sweat and moisture. It is best to use a liquid non-abrasive cleaner and water/soap solution followed by drying the unit.

Wipe Down / Cleaning

To prevent the build-up of rust and other forms of corrosion, wipe down the cycle at the end of each day (or preferably at the end of each class). Raise all posts to the highest setting to expose moisture. Using an absorbent cloth, focus on all areas that perspiration can settle. Give particular attention to the following areas:

- Handlebar

- Seat / adjustable slide for the seat

- Flywheel

- Back leg assembly

- Chain guard

- Brake knob and bolt assembly

- Pop-pins

- Leveling feet

NOTE: Never use abrasive cleaning liquids or petroleum-based solvents when wiping down the cycle.

NOTE: It is recommended that class instructors direct class participants to release all the tension from the cycle at the end of each class to allow perspiration to evaporate.

WEEKLY MAINTENANCE Facilities, MONTHLY Residential

Weekly to monthly maintenance should focus on the overall performance of the bike(s). During these inspections, look for vibration and possible loose assemblies.

Have an experienced rider ride each cycle to identify and help diagnose any vibration, noises, and any “unusual” feeling from the drive chain. Either faulty flywheel alignment or a loose chain can cause vibration.

- Check for proper flywheel alignment. Torque flywheel nuts as necessary. This one is mostly for commercial use.

- Remove chain guard and check for loose chain. Adjust chain as necessary. This one is mostly for commercial use.

- Inspect the bottom bracket Assembly (BBA). The BBA will come loose periodically and require

tightening. Loose play (left and right motion) indicates the BBA needs adjusting. - Inspect each cycle for loose assemblies, parts, bolts and nuts. Give particular attention to the

following: - Tighten all frame base hardware.

- Tighten all pull pin handles.

- Tighten seat hardware.

- Tighten pedal toe clip / toe straps.

- Inspect and tighten tension knob assembly. This one is mostly for commercial use.

MONTHLY for Facilities & Anually for Residential MAINTENANCE

The monthly maintenance check should be a comprehensive inspection of the overall frame and main assembly components of the group cycle.

Inspection

Either call a professional in (http://www.treadmilldoctor.com/find-local-service) or do these things yourself:

Inspect the frame and main assembly components for rust or corrosion. Tilt the cycle or place in an upside down position to locate areas where rust and corrosion may develop. Use a small, wire brush to remove rust build-up in small crevasses, such as leveling feet, pop pin handles and other bolt assemblies. Give particular attention to the following areas:

- Leveling feet

- Pop pin handles

Inspect all wear items for adjustments or possible part replacement. Give particular attention to the following:

- Inspect brake pad for wear. Excessive wear, such as glazing or leather separation, indicates

replacement is required. - Inspect seat pad for wear. Rips, tears or excessive movement indicates replacement is required.

- Inspect pedals for play. Excessive movement of pedals indicates replacement is required.

Comments - 0